文章很精彩,產(chǎn)品更加優(yōu)秀,請點擊上方導(dǎo)航欄選擇您喜歡

的產(chǎn)品或者案例觀看!

很多人喜歡看美國大片,無疑是被大片里面的精彩場面所吸引。但是這些大片中通常有一個角色功不可沒,那就是—機器人。他們刀槍不入、神奇白怪;他們上天入地、亦正亦邪。在欣賞大片的時候我們也總幻想自己身邊能有一個可以談心聊天、照顧我的起居、懂我的喜怒哀愁的機器人。

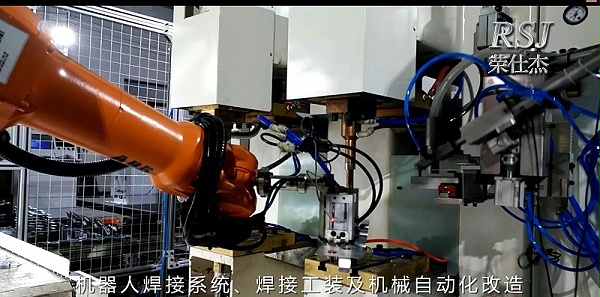

雖然當(dāng)今的機器人盡管沒達(dá)到如此人性化的地步,但在延伸人的手腳、智能化方面已經(jīng)取得很大成果。譬如工業(yè)機器人,在工業(yè)生產(chǎn)制造上代替人完成了許多不可完成的任務(wù),創(chuàng)造了人類奇跡。今天我們就來聊聊關(guān)于工業(yè)機器人的那些事!焊接機器人具有性能穩(wěn)定、工作空間大、運動速度快和負(fù)荷能力強等焊接機器人 特點,焊接質(zhì)量明顯優(yōu)于人工焊接,大大提高了點焊作業(yè)的生產(chǎn)率。主要用于汽車整車的焊接工作,生產(chǎn)過程由各大汽車主機廠負(fù)責(zé)完成。

弧焊機器人主要應(yīng)用于各類汽車零部件的焊接生產(chǎn)。在該領(lǐng)域,國際大型工業(yè)機器人生產(chǎn)企業(yè)主要以向成套裝備供應(yīng)商提供單元產(chǎn)品為主。

3、機器人制造廠商及其集成商(制造和銷售方)需求大量制造、設(shè)計集成、安裝調(diào)試、銷售及技術(shù)服務(wù)工程師和技術(shù)員。使用工業(yè)機器人的客戶(購買方)需求大量操作與維護、編程與調(diào)試、維修與保養(yǎng)等應(yīng)用工程師。

英文版:

Many people like to watch American blockbusters, which is undoubtedly attracted by the highlights in the blockbuster. But there is usually one character in these big movies that is indispensable, that is, the robot. They are invulnerable and magical,

and they are strange and strange. When we appreciate the blockbuster, we always imagine that we can have a robot that can talk and take care of me, and understand my anger and mourning.

Although today's robots have not reached such a human

level, they have achieved great results in extending people's hands and feet and intelligence. For example, industrial robots have replaced many unfinished tasks in industrial production and created human miracles. Today we will talk about those things

about industrial robots!

Components of industrial robots

Industrial robots consist of three basic parts: the main body, the drive system and the control system.

1. The main body is the base and the actuator, including the arm, the

wrist and the hand, and some robots and walking mechanisms. Most industrial robots have 3 to 6 degrees of freedom of movement, of which the wrist usually has 1 to 3 degrees of freedom of movement;

2. The drive system includes a power unit and

a transmission mechanism for causing the actuator to generate corresponding actions;

3. The control system issues command signals to the drive system and the actuator according to the input program, and controls.

Industrial robot features

1, programmable. Further development of production automation is flexible start-up. Industrial robots can be reprogrammed as their working environment changes. Therefore, it can play a very good role in a flexible manufacturing process with small

batches and multiple varieties with balanced and high efficiency. It is an important part of flexible manufacturing systems.

2. Personification. Industrial robots have similar mechanical walking, waist, arms, arms, wrists, and claws on the mechanical

structure. There is a computer in control. In addition, intelligent industrial robots have many human-like “biosensors” such as skin contact sensors, force sensors, load sensors, visual sensors, acoustic sensors, and language functions. Sensors improve

the ability of industrial robots to adapt to the surrounding environment.

3. Generality. In addition to specially designed dedicated industrial robots, general industrial robots have better versatility when performing different tasks. For example,

replacing industrial robot hand end operators (hands, tools, etc.) can perform different tasks.

4, industrial machine technology involves a wide range of disciplines, summed up is the combination of mechanical and microelectronics - mechatronics

technology. The third generation of intelligent robots not only have various sensors for acquiring external environmental information, but also have artificial intelligence such as memory ability, language understanding ability, image recognition

ability, reasoning and judgment ability, etc. These are all applications of microelectronic technology, especially computer technology. The application is closely related.

Today's industrial robot technology is gradually developing towards the

ability to walk, have multiple sensing capabilities, and have a strong adaptive ability to the working environment.

Industrial robot classification

1. Mobile Robot (AGV)

Mobile robot (AGV) is a type of industrial robot. It is controlled

by computer and has functions such as mobile, automatic navigation, multi-sensor control, network interaction, etc. It can be widely used in machinery, electronics, textile, cigarette, medical, food, Flexible handling, transmission and other functions

in the papermaking industry.

2. Spot welding robot

The welding robot has the characteristics of stable welding robot, large working space, fast moving speed and strong load capacity. The welding quality is obviously better than manual

welding, which greatly improves the productivity of spot welding. It is mainly used for the welding work of automobile vehicles. The production process is completed by the major automobile OEMs.

3. Arc welding robot

Arc welding robots

are mainly used in the welding production of various types of automotive parts. In this field, international large-scale industrial robot manufacturers mainly provide unit products to complete equipment suppliers.

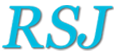

4. Laser processing robot

The laser processing robot applies robot technology to laser processing, and realizes more flexible laser processing operations through high-precision industrial robots. The system is operated online through the teaching box or offline. The system

generates a model of the workpiece by automatically detecting the workpiece, and then generates a machining curve, which can also be directly processed by using CAD data. It can be used for laser surface treatment, punching, welding and mold repair

of workpieces.

5. Vacuum robot

A vacuum robot is a robot that operates in a vacuum environment and is mainly used in the semiconductor industry to realize the transmission of wafers in a vacuum chamber. Vacuum manipulators are difficult

to import, restricted, large in quantity, and versatile, which has become a key component that restricts the research and development progress of semiconductor equipment and the competitiveness of the whole machine.

6. Clean robot

A clean

robot is an industrial robot used in a clean environment. As the level of production technology continues to increase, its requirements for the production environment are increasingly demanding. Many modern industrial products are required to be produced

in a clean environment. Clean robots are the key equipment for production in a clean environment.

Industrial robot application

With the depth and breadth of industrial robot development and the improvement of robot intelligence, industrial

robots have been applied in many fields. Extending from the traditional automotive manufacturing field to the non-manufacturing field. Such as mining robots, construction robots, and hydropower systems for maintenance and repair robots. There are

more and more applications of industrial robots in the fields of national defense, military, medical and health, food processing, and life services.

Qixing Industrial Robot Application and Maintenance

■ Training objectives

For the

first-line training of industrial sites, with good professional ethics, law-abiding, honesty, dedication, and responsibility, can be engaged in industrial robot equipment, mechatronics equipment, electrical automation equipment operation and maintenance,

programming and debugging, installation and maintenance, sales and after-sales service And other work, with good operational experience, can carry out production operations management, high-quality skilled talents with innovative spirit and entrepreneurial

awareness.

■Main Course

Electrical foundation, mechanical design basis, production operation management, automatic control principle, industrial robot technology, single chip principle and application technology, programmable controller

technology, human-machine interface control technology, servo drive technology, sensor and detection technology, hydraulic and pneumatic control System installation and maintenance, communication network technology, industrial robot application and

maintenance technology, FMS flexible control system installation and commissioning.

■ Employment direction

Main application areas: Automotive, modern manufacturing, electronic manufacturing companies, plastic products, food, beverages,

medicine, tobacco, housekeeping services, power facilities, automated office and other industries. Especially in rough manufacturing, stamping, die-casting, forging, machining, welding, heat treatment, surface coating, loading and unloading, assembly,

transportation, inspection and warehouse stacking, industrial robots are widely used as standard equipment.

1. Industrial robot manufacturers: assemblers and commissioners of industrial robots and mechatronics equipment

2. Industrial robot

sellers: professional sales personnel of industrial robots and mechatronics equipment, after-sales technical service personnel

3. Industrial robot users: sales and after-sales technical service personnel of industrial robots and mechatronics

equipment

4. Self-employment: Engaged in the business of electrical automation control, mechatronics equipment development, design, transformation and other projects.

■ Employment advantage

1. In 2000, the number of industrial robots

in China was only 3,500. By 2013, this data had jumped to more than 150,000. Experts predict that the average annual growth rate is expected to maintain 25%. At present, China has surpassed Japan to become the world's largest robot market, and basically

reached the level of automation in 2025.

2, "the robot strategy in the industrial era" is bound to lead to a batch of production personnel to switch (a robot can also replace 2-4 skilled workers). But at the same time, the emergence of large-scale

robots will also spawn a lot of new jobs, including the development, control and maintenance of robots.

3. Robot manufacturers and their integrators (manufacturers and sellers) require extensive manufacturing, design integration, installation

and commissioning, sales and technical service engineers and technicians. Customers who use industrial robots (purchasers) require a large number of application engineers for operation and maintenance, programming and commissioning, repair and maintenance.